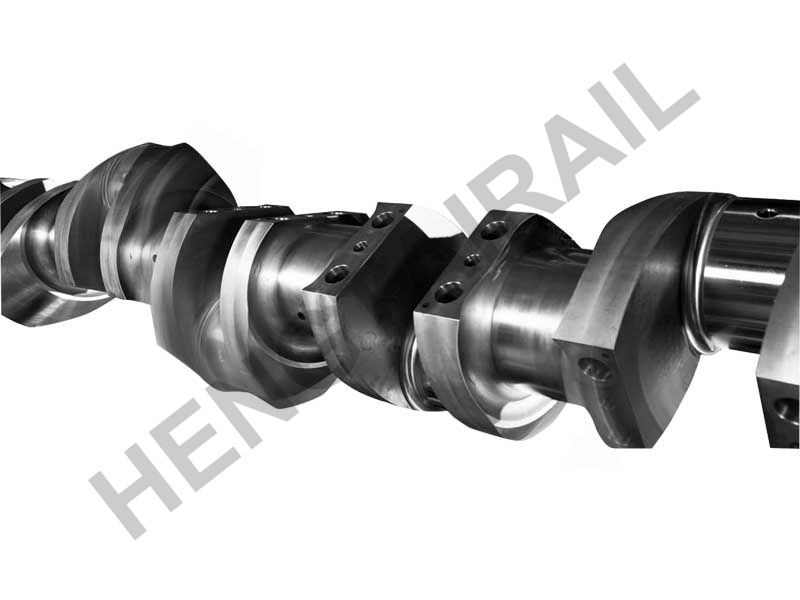

The crankshaft is the most important part of the engine. It bears the force transmitted by the connecting rod and converts it into torque to output through the crankshaft and drive other accessories of engine to work. The crankshaft is subjected to the combined action of the centrifugal force of the rotating mass, the periodic gas inertial force and reciprocating inertial force, so that the crankshaft shall withstand the action of bending and torsion loads. Therefore, the crankshaft is required to have sufficient strength and rigidity, and the surface of its journal needs to be wear-resistant, work uniformly, and have good balance.

Features:

1) Technical index of materials such as chemical composition, Hydrogen (H) and Oxygen (O) content, macro purity and micro purity are optimized. Material conforms AMS 2304, ASTM E381, ASTM E45, ASTM E112, DIN 50602, SEP 1584, etc. standards.

2) Medium-frequency hardening to harden the crankshaft surface, hardening depth can reach 8mm.

3) Inner wall roughness of various oil holes of the crankshaft could reach Ra≤3.2.

4) The straightness of a single journal can be controlled within 0.005mm, the full-length run-out of crankshaft can be controlled within 0.03~0.08mm.

5) Unique journal surface polishing process can make the crankshaft oil hole orifice and journal surface roughtness up to Ra0.2μm.

Advantages:

1) We has passed the certifications of IRIS, EN 15085-2, ISO 10012. The marine crankshaft have passed CCS, ABS, KR, NKK, BV, LR, RINA, GL, DNV, and RS classification societies of 10 countries.

2) We can recommend the choice of crankshaft materials, the matching of mechanical properties, the treatment of strengthening journal surface, the type of crankshaft fillet and the method of strengthening, so as to assist customers to improve the design of crankshaft, according to performance index and structural features of diesel engine.

3) The crankshaft development has been using DEFORM simulation software to simulate material flow, forging load, mold stress and grain evolution, fully considering the requirements of product quality required by customers, and taking the best fiber flow, the opimum machining allowance & the most economical forging cost as selection principle of forging tehcnical process. We can calculate the changes of product temperature and structure in quenching process by DEFORM software, and use test-pieces to simulate and work out appropriate temperature, time, cooling and other parameters of heat treatment processing. Our patented time-controlled cooling technology can work out individual quenching cooling curve for crankshafts with different material and size, and microcomputer control can realize manufacture process reproducibility perfectly.

4) On the crankshaft surface treatment, we use medium-frequency hardening to harden the crankshaft surface so that the surface hardening depth can reach 8mm. When the crankshaft round root design adopts the inner round root, we can provide customers with round root shot peening and rolling, so as to strengthen the surface and increase the fatigue life of the crankshaft.

5) The crankshaft can run quietly in diesel engine by using our extensive practical experience in both digital control and dynamic balance. We also can provide customers with crankshaft system directly assembled in diesel engine, including balance weight, crankshaft connecting bolt, gear and oil plug. All crankshafts cannot put on the market until they are re-tested, cleaned and fully confirmed and fully recorded after assembly.

We could provide you with the large and medium-sized crankshaft, the range is covered as follows:

| Length | Less than 8500mm |

| Diameter | Within Ф400mm |

| Turning diameter around main journal center | Ф1250mm |

| Turning diameter around rod journal center | Ф1600mm |

| Weight | Within 12.5T |

| Stroke | Less than 600mm |

We already developed:

1) EMD645 (12 cylinders, 16 cylinders) crankshaft;

2) EMD710 crankshaft, Alco crankshaft (12 cylinders, 16 cylinders);

3) CKD locomotive engine crankshaft;

4) DF series locomotive engine crankshaft;

5) HXN series locomotive engine crankshaft, etc.

6) Beside, we also supplied the marine crankshaft for G32 series, MAN series, DK series, etc.

Application:

1) EMD645 (12 cylinders, 16 cylinders) crankshaft,

2) EMD710 crankshaft, Alco crankshaft (12 cylinders, 16 cylinders),

3) CKD locomotive engine crankshaft,

4) DF series locomotive engine crankshaft,

5) HXN series locomotive engine crankshaft,

6) Marine crankshaft for G32 series,

7) MAN series, DK series, etc.

Our crankshaft have been sold to more than 10 countries and regions, including Germany, Denmark, France, South Korea, India, South Africa, Egypt, and Argentina, etc.