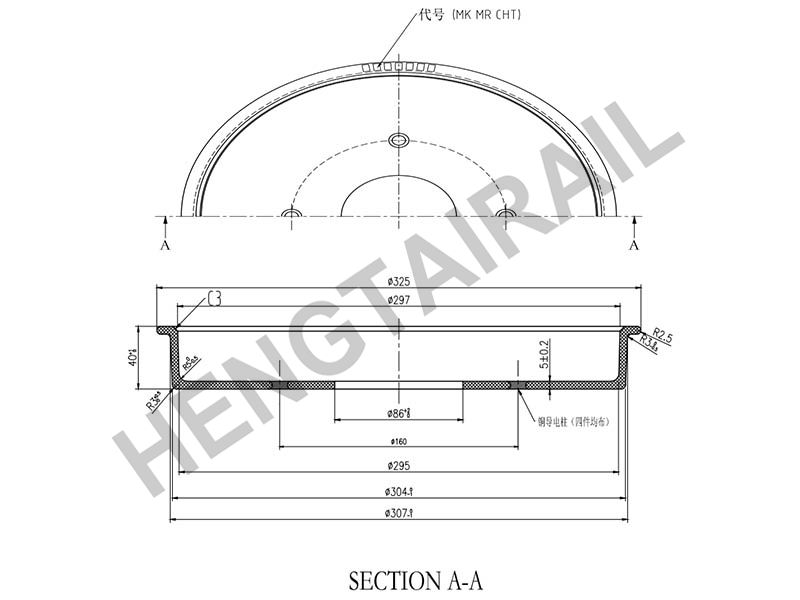

The wear plate (liner) of the center plate of railway freight car is made of special nylon material, which is manufactured by die casting and cutting, and has good wear resistance.

The installation of center plate wear plate (liner) between the upper and lower center plates can solve the question of serious wear of upper and lower center plates.

At the same time, it is helpful for the stability of turning resistance moment of car body relative to bogie.

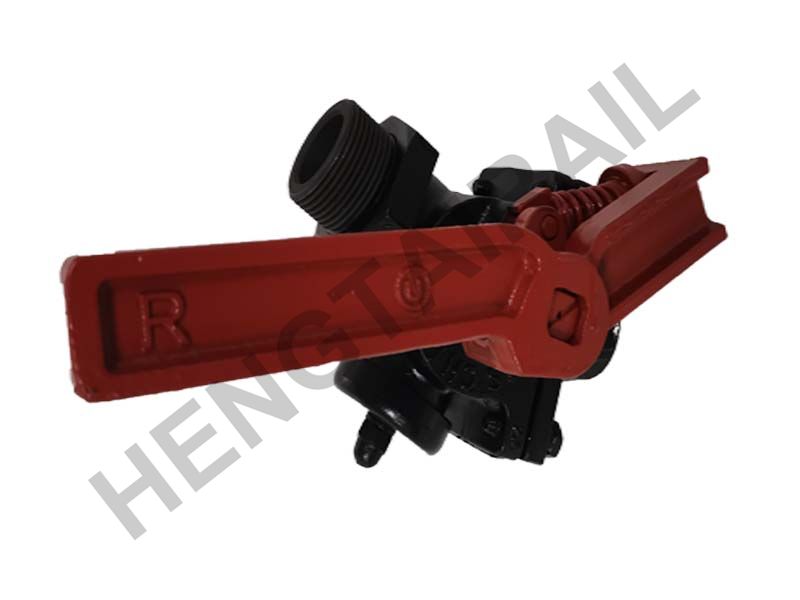

Features:

1) Enhanced cold flow resistance.

2) Heavy duty forged construction.

3) Designed for high mileage.

4) Easy to install – no lubrication required.

5) Prevents center plate and center bowl wear.

6) coefficient of friction, high wear resistance.

| General properties | Test Method | Unit | Data |

| Hardness | GB/T2411 | HD | 75 |

| Tensile strength | GB/T1040.1 | Mpa | 48 |

| Elongation at break | GB/T1040.1 | % | 70 |

Notch impact strength 23℃ -50℃ | GB/T1043.1 | kJ/m2 | 6 12 |

| Bend strength | GB/T9341 | Mpa | 5 |

| Compressive strength | GB1041 | Mpa | 120 |

| Vicat softening temperature | GB/T1633 | ℃ | 210 |

| Water absorption | GB/T1034 | % | 0.9 |

| Density | ISO1183 | g/cm3 | 1.07 |

| Heat deflection temperature 1.8Mpa 0.45Mpa | ISO75-1/2 | ℃ | 18 205 |