Introduction:

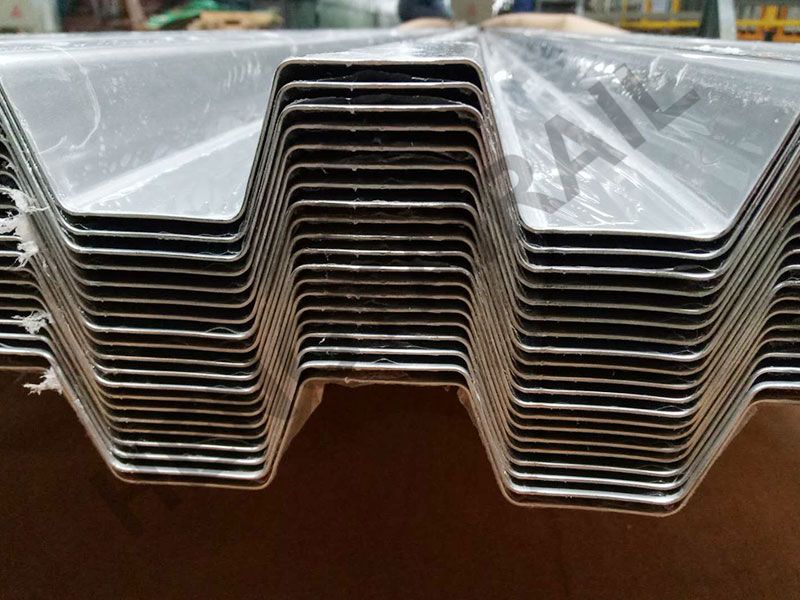

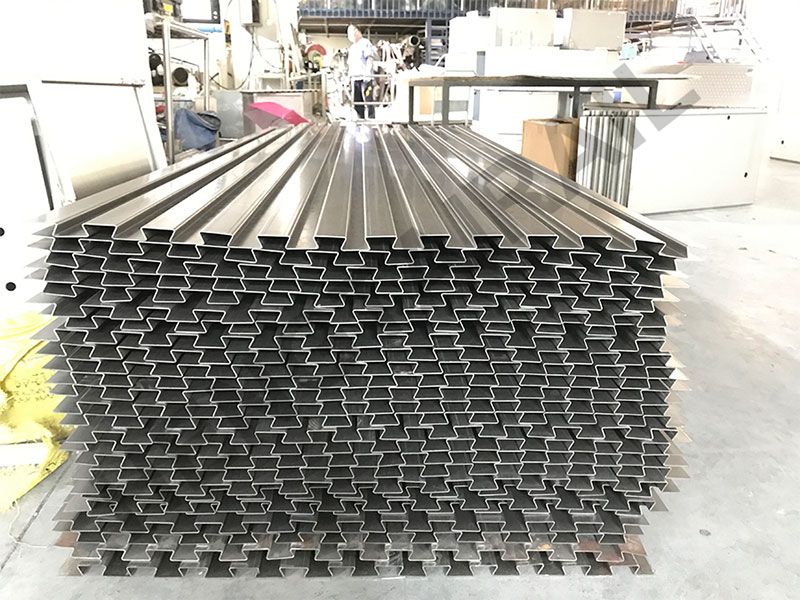

The corrugated floor is made of rolled steel raw materials through the rolling process to bend and stretch. The surface hardening of the material after drawing improves the material performance. Due to the internal stress generated by the interaction within the drawing metal during the drawing process, the thickness and surface area of the material will change under the combined action of the tensile stress generated in the radial direction and the compressive stress generated in the tangential direction. After the material is hardened The yield limit and flexural resistance will be greatly improved. It is easy to install and has excellent mechanical properties.

High strength structure with excellent load-bearing, sound proof, fire-retardant performances.

Application:

Used in railway carriages, bathrooms, kitchen.. etc

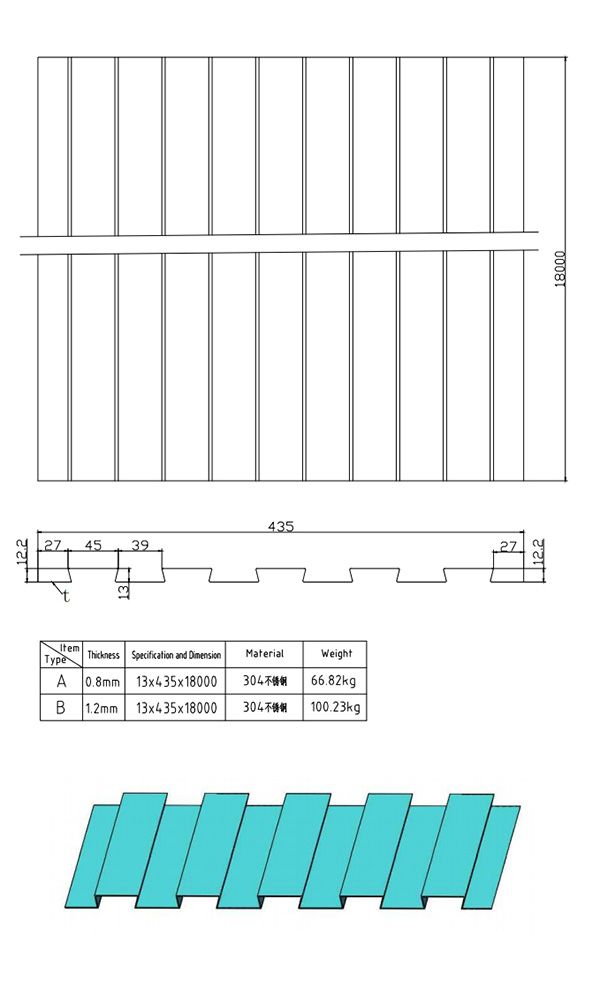

Dimension: 18000mmx435mmx13mm/T=0.8mm

Weight: around 60Kg

Material: Q275/Q345/SS304

Process: rolling or bending

Mould opening is available

Delivery time: 60 days

There are many types of ripple, through custom design to meet customer requirements