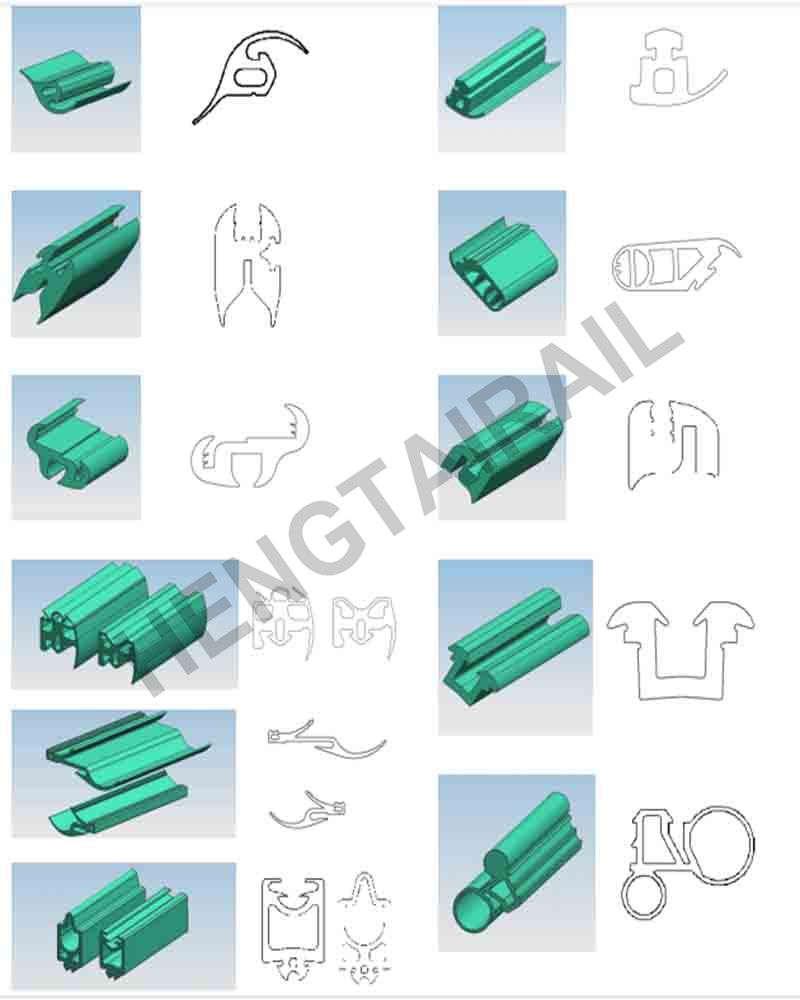

The sealing strip for the doors of subway trains and high-speed trains is made of ethylene propylene diene monomer (EPDM) rubber, which is extruded using microwave vulcanization technology in one go. The surface is smooth and beautiful, and has good elasticity, compression deformation resistance, aging resistance, ozone resistance, and chemical corrosion resistance.

The sealing strip for the doors of subway trains and high-speed trains also has a wide temperature range, ranging from -20 ℃ to+50 ℃

Its sealing performance is also good.

The subway train high-speed rail door rubber sealing not only has good elasticity, but also has excellent insulation and thermal insulation properties, and strong compression load capacity; Also, due to the convenience, firmness, and reliability of the installation of the subway train high-speed rail door sealing strip, it has good waterproof, dustproof, soundproof, temperature insulation, and shock absorption effects; So it is widely used in sealing places such as subway doors, high-speed rail screen doors, platform door seals, emergency door seals, sliding door seals, etc.

Application

Subway trains and high-speed trains

Related products

Railway door rubber seal

Railway window rubber seal

Subway Shielded door sealant strip

Subway Platform anti step rubber board

High-speed rail Platform anti step rubber board

Train Door and Window Sealant Strip Series

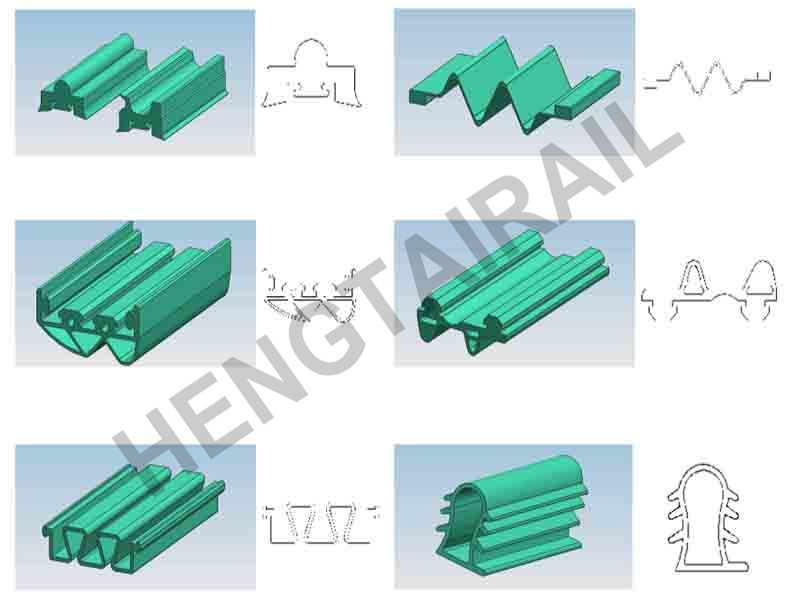

Shielded door sealant strip

Mainly used for sealing of shielded doors

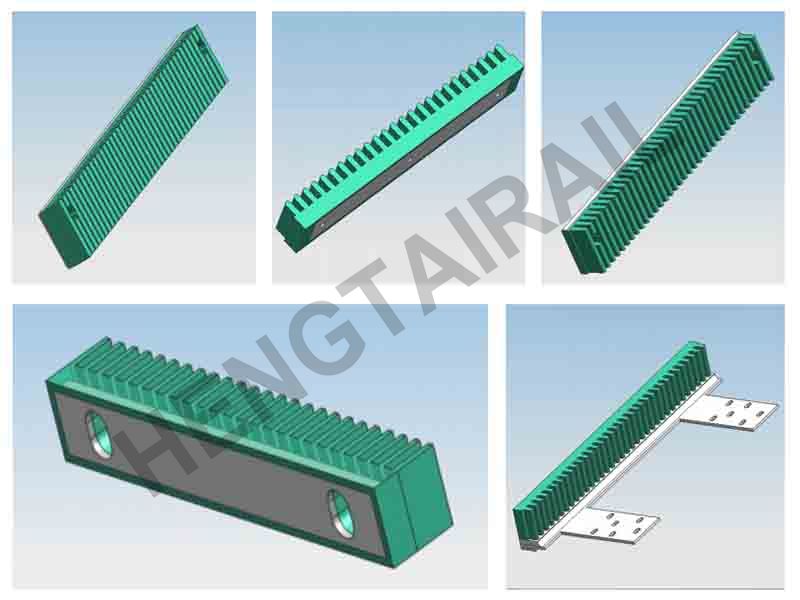

Train Anti trampling

Used for and the gap between the train platform, to prevent air passengers.

| Name | Rubber seal |

| Colour | Black |

| Type | Per drawing, accept customization |

| Material | EPDM, accept customization |

| Hardness | ±50 Sha |

| Tensile Strength | >7 MPA |

| Elongation at Break | >350 |

| Brittle | -45℃ |

| Temperature | -20℃~+50℃ |

Advantage

1. Good ozone resistance and tensile strength;

2. Good resistance to high and low temperatures, as well as wear resistance;

3. Significant in chemistry and various interstitial solutions;

4. Good insulation and oxygen resistance performance;

5. Good sealing performance, good elasticity and resistance to compression deformation.