Superior Material: Made from special high-strength steel with strict chemical composition control and heat treatment processes, providing excellent wear resistance and fatigue performance.

Advanced Design: The wheel design utilizes Computer-Aided Engineering (CAE) technology to optimize the structure of the wheel rim and tread, enhancing load capacity and operational stability.

Precision Machining: High-precision CNC machining ensures precise geometric dimensions and superior dynamic balance, reducing vibration and noise during operation.

Wear Resistance: The surface undergoes a special hardening treatment to form a robust protective layer, significantly improving the wheels' wear resistance and extending their service life.

Safety Performance: Each wheel is subjected to rigorous non-destructive testing and static load testing to ensure there are no defects, maintaining stability and safety during high-speed operation.

Environmentally Friendly and Energy-Saving: Optimized design and manufacturing processes reduce energy loss during operation, helping to improve the train's energy efficiency ratio and lower operational costs.

Wide Application: Suitable for various types of railway vehicles, including high-speed trains, freight trains, subways, and light rails, meeting the demands of different working conditions.

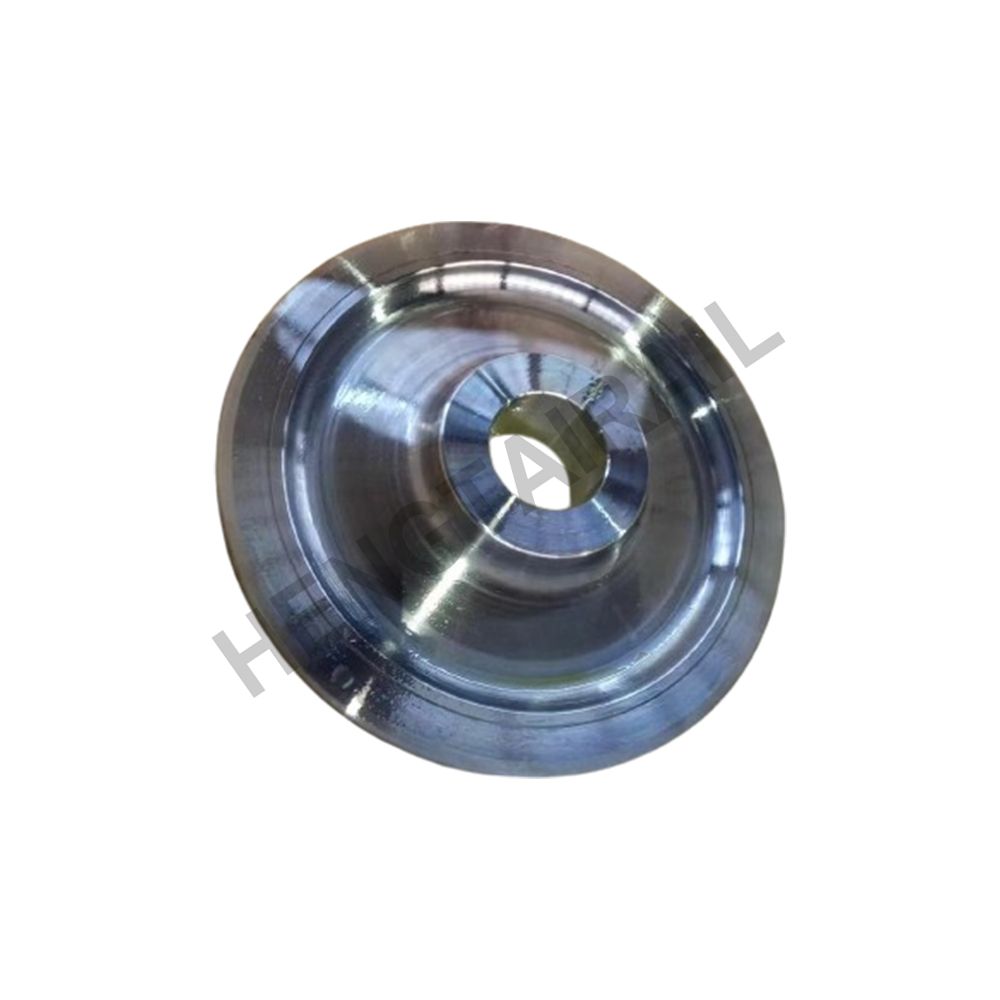

AAR Standard Wheel Disc Used Train Wheels for Railway Wagons

Train wheels are the key components of railway vehicles, they bear the important role of supporting the body, transferring the load and providing traction. Modern train wheels are usually made of high-strength steel materials to ensure adequate durability and safety.

- Description